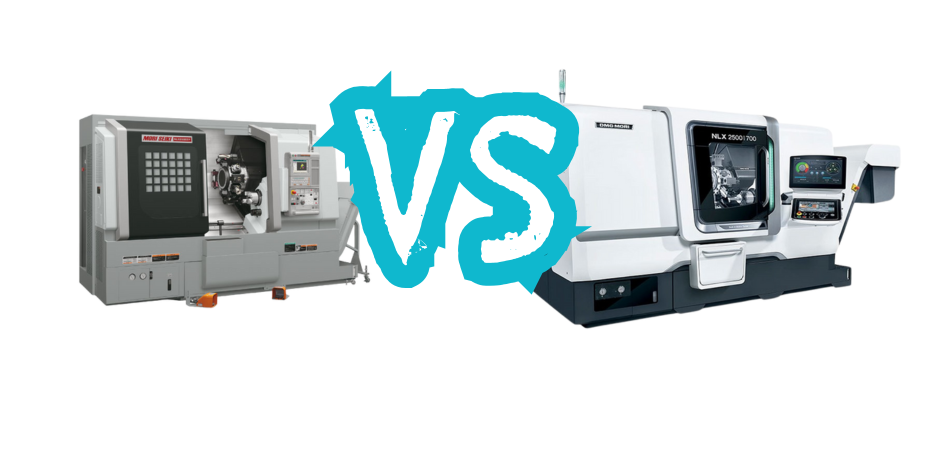

Mori Seiki vs DMG MORI Lathes: Old vs New CNC Turning Centers Compared

- Dec 16, 2025

- 4 min read

If you’re a machine shop owner, manufacturing engineer, or operations manager comparing Mori Seiki vs DMG MORI lathes, this guide breaks down the real-world differences between older Mori Seiki CNC lathes and newer DMG MORI turning centers—from reliability and cost to automation and long-term ownership.

This comparison is especially relevant for shops searching locally or regionally for used Mori Seiki lathes for sale or used DMG MORI lathes near me, where availability, service support, and total cost of ownership matter as much as specifications.

Mori Seiki and Gildemeister (DMG) officially partnered in the early 2010s, later consolidating under the DMG MORI brand(Source: Wikipedia – https://en.wikipedia.org/wiki/DMG_Mori).While branding changed, many shops still draw a clear line between legacy Mori Seiki machines and modern DMG MORI CNC lathes when making purchasing decisions.

What Tends to Be Better About Older Mori Seiki Lathes

1. Simple, Rugged, “Keep It Running” Design

Many older Mori Seiki lathes—including SL-series and early NL-series machines—are known for extremely rigid castings and conservative mechanical design.

Compared to newer machines, legacy Mori Seiki CNC lathes typically feature:

Fewer sensors and interlocks

Simpler electrical and I/O systems

Easier diagnostics for local service technicians

For shops without full OEM service contracts, this simplicity often translates into better uptime and faster in-house repairs.

2. Familiar Fanuc-Based Controls

A large percentage of used Mori Seiki CNC lathes are equipped with Fanuc controls, which remain widely supported across North America and globally.

Benefits include:

Easier hiring and operator training

Broad third-party service and parts availability

Simpler retrofits and custom automation integrations

For regional shops running multiple Fanuc machines, adding a used Mori Seiki lathe is often seamless.

3. Lower Acquisition Cost and Reduced Risk

From a financial perspective, used Mori Seiki lathes for sale offer excellent ROI:

Lower upfront capital cost

Proven designs with long service life

Easier justification for dedicated or repeat jobs

This is why many small to mid-sized shops prefer sourcing older Mori Seiki machines locally rather than committing to new-machine lead times and pricing.

What Tends to Be Better About New DMG MORI Lathes

DMG MORI’s current turning lineup includes CLX, CTX, NLX, NL, SL, and advanced turn-mill platforms like the NTX and CTX TC(Source: DMG MORI – https://www.dmgmori.com).

These machines are designed to maximize output, especially in high-mix or automation-heavy environments.

1. Capability per Square Foot (Turn-Mill Advantage)

New DMG MORI lathes shine when combining multiple operations into one setup. Depending on the model, features may include:

Y-axis and B-axis milling

Subspindles and lower turrets

Full 5-axis turn-mill capability

The DMG MORI NLX series is positioned as a high-performance turning center with modern rigidity, speed, and accuracy(Source: DMG MORI NLX Series – https://www.dmgmori.com/products/machines/turning/universal-turning/nlx).

2. Automation and Lights-Out Readiness

Compared to legacy machines, DMG MORI turning centers are built with automation in mind, offering better OEM integration for:

Bar feeders

Robotic loading systems

Pallet automation

In-process probing and monitoring

For shops pursuing lights-out machining or regional contract manufacturing work with tight labor constraints, this is a major advantage.

3. Digital Tooling, Data, and Connectivity

Modern DMG MORI CNC lathes are designed for connected manufacturing environments, supporting:

Machine monitoring and job tracking

OEE and utilization analysis

Production traceability

These features are increasingly important for aerospace, medical, and automotive suppliers.

4. Speed and Throughput Improvements

Newer machines often deliver better acceleration, spindle performance, coolant management, and chip evacuation—especially valuable for complex parts or multi-axis applications(Industry reference: Ex-Factory – https://www.exfactory.com).

Day-to-Day Tradeoffs: Old Mori Seiki vs New DMG MORI

Reliability

Older Mori Seiki lathes: Often extremely reliable if maintained, though age-related issues (drives, encoders, lubrication systems, ballscrews) should be expected.

New DMG MORI lathes: Mechanically excellent, but increased software layers and interlocks can occasionally lead to non-mechanical downtime.

Service and Parts Availability

Used Mori Seiki machines: OEM parts may take longer, but third-party service providers are widely available in most regions.

New DMG MORI machines: Strong factory support and current parts availability, often tied to OEM service agreements.

Total Cost of Ownership

Older Mori Seiki machines win for stable production, known processes, and strong in-house maintenance.

New DMG MORI machines win where automation, setup reduction, and process consolidation drive profitability.

Finding Used Mori Seiki and DMG MORI Lathes Near You

For many shops, the best solution is sourcing a used Mori Seiki or used DMG MORI lathe locally or regionally, reducing freight costs and speeding up installation.

A well-maintained used Mori Seiki lathe can deliver decades of service, while used DMG MORI lathes for sale often provide modern capability without new-machine pricing or lead times.

If you’re searching for:

Used Mori Seiki lathes near me

Used DMG MORI CNC lathes in the U.S. or North America

Late-model DMG MORI turning centers for sale

Compare used Mori Seiki lathes for sale by model, year, and location

Find used DMG MORI lathes available regionally

Evaluate pricing, specs, and availability side by side

This approach often allows shops to step into higher-end machines while controlling capital risk.

Which Should You Buy? A Quick Rule of Thumb

Choose an older Mori Seiki lathe if your priority is lower cost, proven reliability, and local service flexibility.

Choose a new or newer DMG MORI lathe if your priority is automation, turn-mill capability, setup reduction, and connected manufacturing.

Either way, understanding the differences—and shopping the used market strategically—can significantly improve ROI.

Comments